Architecting Cloud Industrial IoT Workloads – Part 1: Use Cases and Challenges

- June 28, 2022

Top industry analysts identify IoT and AI/ML as the top domains of innovation involving cloud technologies. Clearly, the cloud providers agree! In 2021 alone, you can see that AWS made 72 announcements and Azure made 67 announcements related to IoT just by browsing their websites. At the time of writing this article, we counted 14 new announcements for both AWS and Azure so far in 2022. Advanced IoT implementations are usually integrated with Machine Learning services. In this space, we counted 110 announcements from AWS in 2022 and 24 for Azure. This massive R&D investment made by cloud providers shows the industry’s high expectation for IoT growth.

IoT technologies can be applied to a wide range of industries and use cases. There are 3 categories of IoT: Commercial, Consumer, and Industrial. This 3-part blog series focuses on industrial clients’ implementation of Industrial IoT – IIoT – with cloud technologies. This 3-part blog series focuses on industrial clients’ implementation of Industrial IoT – IIoT – with cloud technologies. In this first part, we will discuss the IIoT use cases, how they are architected at a very high level and the challenges of the clients’ cloud IIoT journey. In the 2nd part, we will deep dive in an AWS implementation. The 3rd part will focus on Azure IIoT implementation.

Three Industrial Challenges That IIoT Solves

1 - Gain Visibility in the Operations

On a plant floor, we can find a wide range of equipment vendors and models, which means a wide range of data models and protocols. Collecting data from each silo, transforming it and storing it in the cloud allow industrial companies to analyze the data and find ways to optimize operations. This is typically first step of an IIoT strategy. This is typically the first step of an IIoT strategy. If the equipment in place does not produce the data needed, it may be possible to collect additional data by adding a separate sensor or device such as the Amazon Monitron which collects vibration and temperature data. Both AWS and Azure have a catalog of their partner certified devices and sensors.

Once you have access to the consolidated data, a wide range of opportunities opens. You can monitor the overall production in real time. You can also compare different pieces of equipment, production line and plant performance over time.

AWS’ Volkswagen case study is a great example of a successful large-scale IIoT implementation. Connecting thousands of sensors and systems to the cloud, they can increase productivity and reduce costs.

2 - Reduce Productivity Waste

Productivity can be disrupted in many ways. For example, a piece of equipment can break. If you can use the data collected to build a digital twin and predict failure as opposed to react to it, you can prevent or mitigate the disruption. The most advanced IIoT implementations allow to automatically act without human intervention: think of a self-healing mechanism.

Another productivity waste could come from goods being produced with a defect. If an anomaly is not detected early enough, a lot of materials, time and energy could be wasted as well as customer satisfaction impacted if it reaches the customers. IIoT solutions can detect anomalies early and prevent such scenarios.

IIoT solutions also help extending the lifespan of equipment. It leads to obvious cost savings but in a time of uncertainty with the supply chain, it also means higher throughput.

Additionally, industrial companies can optimize productivity by automating integration with partners, suppliers, equipment suppliers and logistics partners and even reduce human error that can be introduced

NTT DATA helped a large solar and wind energy producer to optimize their productivity. Using Azure Digital Twins and IoT Hub, we were able to reduce productivity waste by accurately predicting production output to meet production target as well as minimize operations and maintenance costs.

3 - Meet Ambitious Sustainability Goals

According to the US Energy Information Administration, industrials are the largest consumer of energy in the US. And within this group, manufacturers account for 81% of the energy consumption. Optimizing energy and water consumption can yield large cost savings and progress towards sustainability goals.

CCI – one of the largest Coca Cola bottlers – used AWS IoT SiteWise, Greengrass and IoT Core to collect, model and ingest data and build advanced analytics. They were able to save 20% annually on energy and 9% on water.

Architecting IIoT Workloads

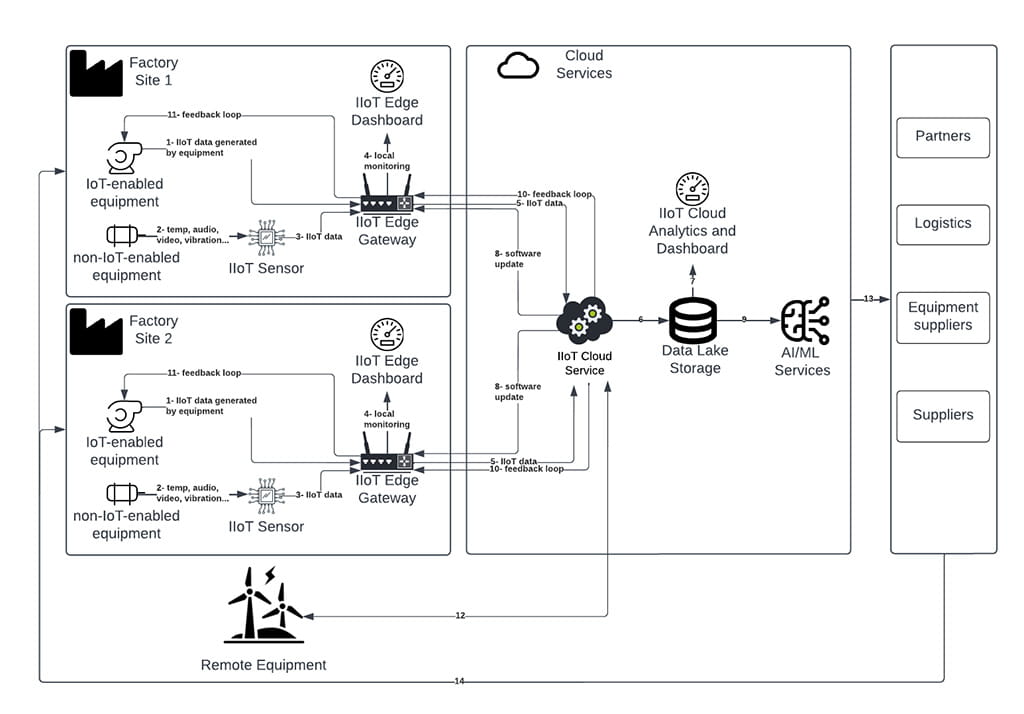

To solve the industrial challenges mentioned above, you can refer to the following architecture diagram. We made this cloud IIoT architecture diagram very high-level so that it can be cloud-agnostic.

The common first step in the cloud IIoT journey is to gain visibility into the operation by collecting, processing, and sending data to the cloud for storage and analysis.

The following numbers will guide you through the architectural diagram from above:

- The data from IIoT-enabled equipment is sent to an IIoT Edge device

- Data from equipment which is not IIoT-enabled can be collected from external sensors

- The IIoT sensor sends the data to an IIoT Edge device

- Operators can monitor the IIoT data from a local dashboard

- The IIoT data is sent to the cloud IIoT service

- The IIoT data from multiple sites and remote equipment is stored, for example in a data lake

- The real-time data and time series can analyzed

Next, you can develop software and push the updates to the edge devices as shown in step 8.

For the most advanced use cases, AI/ML services are used to make predictions and make recommendations as shown in step 9, eg: slowing down or replacing a machine to avoid a bigger failure. The arrows 9 and 10 illustrate how the AI/ML recommendations can be automatically sent to the IoT-enabled equipment.

Similar flows of communication can be applied to remote equipment (11).

Finally, the analysis of the cloud data and be used to integrate with partners, logistics and suppliers (13) to ensure operations are optimized with the factory site (14).

Challenges on the Cloud IIoT Journey

While many industrial leaders are embracing IIoT, there are common concerns involved with this technology adoption. First, it will require training and hiring to gain the wide set of skills required: Big Data, Analytics, Security, Machine Learning and DevOps. There is also the cost of the investment requirement for the digital transformation: hardware, software and services required. Finally, there is a new cybersecurity risk introduced by connecting devices which have traditionally operated offline from the Internet.

According to a report from NTT DATA and Oxford Economics published in January 2022 about Industry 4.0, "while nearly all respondents—more than 95%—are at least in the early stages of implementation, very few have completed the journey". In addition, “manufacturers have not seen impressive results". Microsoft’s IoT Signals report states that “many projects are stuck in Trial/PoC”.

Given the diversity of industrial technology ecosystem and challenges, most IIoT implementations involve a business consultative approach, custom data analysis, and even machine learning models development. In these situations where the business goals are known but the technical solution implementation has a lot of uncertainty, there is a need for experimentation.

Cloud services are well positioned in these situations: they allow rapid deployment, shutdown of cloud resources when no longer needed, iterate to the next idea and scale fast once the value has been proven. However, cloud IIoT workloads are not solely about the cloud. They are hybrid by definition: data must be collected where the equipment is located, then it can be processed and sent and stored in the cloud. From there, we can use compute, analytics, and machine learning services in the cloud.

While there are many adoption barriers, IIoT has enormous potential. This transformation is expected to differentiate industrial businesses in the coming years.

In the next part of this blog series, we will deep-dive into how this architecture is implemented in AWS.

Subscribe to our blog